On November 27, the FDA recommended a voluntary romaine lettuce labeling program for suppliers of processed and bulk romaine grown throughout the United States. This is in response to the recent E. coli issues that led to the FDA’s November 20 directive to remove and destroy all romaine lettuce in the fresh food supply chain.

The FDA is requesting that all romaine lettuce be labeled, whether in bulk, processed or mixed, with the harvest date and location information. This label should be visible on all packaged produce and included on cartons of bulk produce in a way that it is easy for the consumer to discern the harvest time and origin.

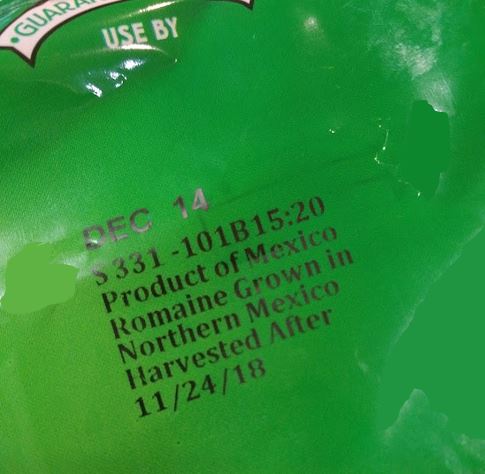

There are a number of approaches to complying with this FDA request. The Produce Marketing Association and United Fresh have jointly published a comprehensive FAQ about the voluntary program. The above photo of a bag of romaine lettuce mix was taken on December 1 in my local grocery store. It features the harvest date and the produce’s harvest location as being in Mexico.

Making Romaine Lettuce Labeling Simpler for Suppliers

This romaine lettuce labeling program, while voluntary, is expected to be the “new normal” for packaged and bulk romaine lettuce going forward. And, while it currently only applies to romaine lettuce, it’s not difficult to imagine that it could ultimately be applied to other lettuces and types of produce.

With the current labor challenges, adding another process step is not likely something that produce suppliers are looking forward to implementing. Zest Fresh can help simplify and automate this process.

Zest Fresh autonomously collects data about each pallet of produce from the point of harvest and easily integrates with your data systems. Pallet-level IoT condition sensors require minimal labor – simply push a button and place the sensor in the pallet. Automated readers at food supply chain waypoints collect the data for cloud-based storage and analysis.

This approach makes it easy to support produce traceability based on the Produce Traceability Initiative (PTI) work completed several years ago. While PTI provides the data for source-level traceability, it does not provide a convenient and reliable way for consumers to access that data in a standardized and trusted way. Zest Fresh does.

For example, combining PTI information (i.e. supplier GTIN, location, harvest date, lot number) with purchase order and shipping information (i.e. Advanced Ship Notice or ASN) provides the basis for all the information required. As a result, consumers are provided with access to the information necessary to reflect the source of the produce they’re purchasing. This would help manage food safety incidents by reliably identifying produce determined not to be affected – so that the unaffected produce could be sold and consumed with confidence.

The Higher Goal: Prevent and Minimize Food Safety Incidents

Addressing consumer concerns via romaine lettuce labeling is an important and good start but we should strive to meet a higher goal that provides complete visibility across the fresh food supply chain.

Zest Fresh takes a proactive approach that delivers “true transparency” across the fresh food supply chain. For example, most processed fresh foods (such as bagged salads) are required to provide a HACCP (Hazard Analysis and Critical Control Points) plan that reflect the steps a processor takes to manage produce contamination risk. The “Critical Control Points” can be reflected in tests that check for potential food contamination and proactively validate produce safety. Zest Fresh makes it easy to add this type of preventive data into the solution which enables instant communication for preventing the distribution of at-risk produce (or proteins) by distributors, retailers and restaurants – before the produce reaches the consumer.

While field-packed produce such as romaine lettuce is not currently required to maintain a HACCP plan, providing a means to proactively manage produce as it moves through the food supply chain encourages this type of testing for all produce. Zest Labs embraces this methodology and incorporates critical test result data directly into its data sets to promote this proactive approach to help prevent or minimize food safety incidents. Zest Fresh also supports integration with blockchains for food to provide additional security and standardization.

Food suppliers using Zest Fresh already have the data they need on their romaine lettuce to address the voluntary labeling program. And, with Zest Fresh, the information is available for other food inventory management systems, such that it doesn’t require workers to read the labels, making it simple for the system to validate if a pallet or case of romaine lettuce is clear for sale. Zest Fresh provides the insights food suppliers, retailers and restaurants need to improve post-harvest operational efficiency and ensure delivered freshness. Learn more about Zest Fresh.

For an additional perspective on romaine lettuce labeling, you may find this article in Consumer Reports of interest. (Published on December 14, 2018)