FRESH PRODUCE

Consistency of delivered freshness a huge challenge.

Despite many advances in produce harvesting, processing and distribution techniques,

there still remains roughly 33% post-harvest waste*

between the farm, retailer and consumer.

Much of this waste is the result of misperceptions...

*UN FAO Global Food Losses and Food Waste

Perception

Reality

Impact

All produce harvested on the same day

will have the same shelf life.

Produce

shelf

life

can

vary

significantly

within

a

single

day's

harvest.

Cut-to-Cool

time

delays

directly

impact

shelf

life.

Cut Time:

7:00 AM @ 65°

Entered Pre-Cooler:

8:15 AM @ 68°

Cut Time:

9:30 AM @ 72°

Entered Pre-Cooler:

5:20 PM @ 83°

Cut Time:

2:30 PM @ 84°

Entered Pre-Cooler:

7:05 PM @ 88°

Your first harvest of the day is at cool morning

temperatures, and goes directly into pre-cool upon

arriving at the pack house. But as the day wears on,

pre-cooler capacity doesn't match the harvest rate, and

pallets back up. As cut-to-cool time grows, and

temperatures rise, product shelf life decreases. If the

reduced shelf life from extended cut-to-cool times is not

tracked, the risk of problems or rejection for deliveries to

distant retailers increases.

Perception

Reality

Impact

Produce pulp temperatures match pre-cooler air temperature when pallets are removed.

Produce

temperatures

can

vary

significantly

after

pre-cooling.

Insufficient

pre-cooling

significantly

reduces

shelf

life.

Pre-cooling is critical to extending shelf life, as it is the primary method of reducing the

respiration rate, which slows ripening or delays decay. Best-use-by dates assume complete

pre-cooling to the safest low temperature for each type of produce. However,

many products are insufficiently pre-cooled due to inaccurate and incomplete tracking of

product pallet temperature. Even small final pre-cool temperature differences can lead to

significant shelf life reduction.

Perception

Reality

Impact

It doesn't matter which pallet ships to the furthest destination because they all have the same remaining days of freshness.

Unaccounted

for

variations

in

remaining

days

of

freshness

can

dramatically

impact

delivered

freshness.

Indiscriminate

routing

results

in

inconsistent

delivered

freshness

and

unnecessary

waste.

Blindly selecting pallets with varying freshness for differing distribution requirements and

transit times leads to disappointment in delivered freshness. The longer the trip or post-delivery distribution needs, the higher the risk. Waste and customer disappointment increases

if you do not ensure the necessary freshness based on distribution time and customer needs

(i.e. retailer versus restaurant).

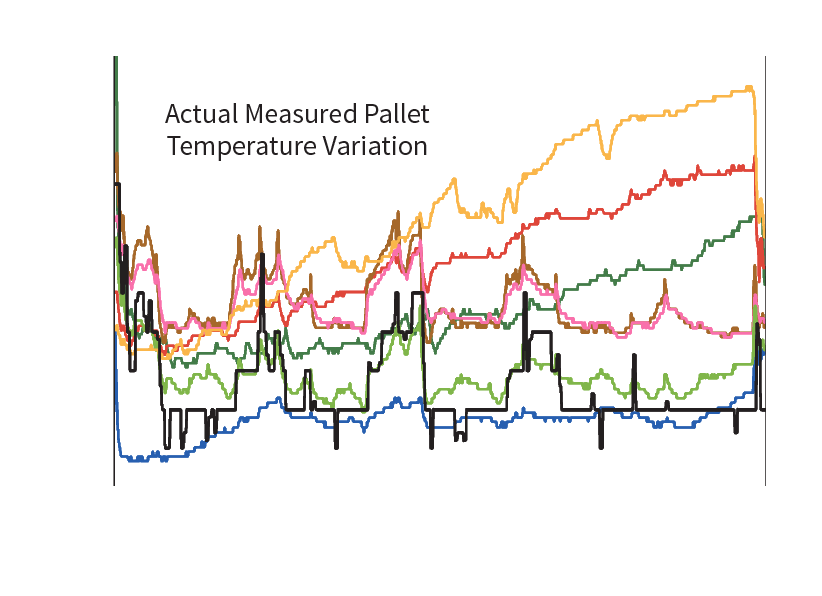

Perception

Reality

Impact

All produce is maintained at the ambient temperature of the trailer.

Significant

pallet-level

temperature

variations

can

occur

within

the

trailer.

In-transit

pallet

temperature

variations

increase

waste

and

risk

of

shipment

rejection.

Studies have shown, that even in, "…well-controlled conditions inside a chilled distribution

container, there were significant temperature variations from pallet to pallet of up to 35

percent."* Trailer level temperature monitoring exposes the supplier to full load rejections,

based on a few bad pallets, and the retailer to accepting bad pallets based on false

assumptions resulting in waste for the retailer.

*Intelligent Cold Chain - Deloitte

Perception

Reality

Impact

Visual inspection is a reliable way to estimate remaining freshness.

Visual

inspection

cannot

reliably

estimate

remaining

freshness.

Produce

is

distributed

that

does

not

meet

retail

freshness

requirements.

Extending shelf life through refrigeration has led to a disconnect between visual freshness

indicators and actual remaining freshness. Fresh picked fruit typically is fresh for 2-3 days.

Refrigeration has extended that to 14+ days, as the ripening or decay process has been

slowed. So visual indicators are lagging indicators, only apparent in the final few days of

remaining freshness, meaning they are only a good screen for consumers–not supply chain

receiving.

Perception

Reality

Impact

All produce received at retail is fresh,

with at least 5 days of remaining shelf life.

Produce

quality

can

vary

significantly

due

to

post-harvest

handling.

Store-level

quality

inconsistency

leads

to

dissatisfied

customers

and

waste.

Grocers maintain and display produce with care, as consumers choose retailers based on

their fresh produce. However, retailers are challenged with maintaining freshness as they

cannot "see" how the produce was previously handled, and the produce is only as fresh as it

was received – which can vary significantly. Without consistent delivered freshness, this

challenge becomes unmanageable, resulting in waste for both the retailer and the consumer.