Post-Harvest Technology

New post-harvest technologies are modernizing the fresh food supply chain. Until recently, growers, processors and suppliers had limited data and visibility into their post-harvest operations. Today, instead of relying on arbitrary or anecdotal data about harvest conditions, cut-to-cool and vehicle or pallet dwell times, post-harvest technology, like Zest Fresh, provides answers and insights.

Zest Fresh combines advanced analytics and machine learning with autonomous IoT condition sensors to enable visibility and actionable insights about what is happening to the produce from harvest through to shipment and provide alerts to identify and address issues before they occur.

Post-harvest Technology for Growers

SaaS-based predictive analytics and machine learning systems coupled with autonomous IoT sensors deliver the ability to more easily collect and evaluate information about the produce including:

Harvest Conditions, Time and Location

You can know the condition and status of each pallet of produce beginning at harvest in the field. Zest Fresh IoT sensors are easily applied in the field and data is autonomously collected throughout processing, from the field to shipment.

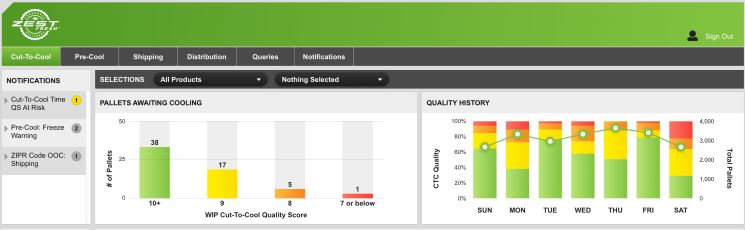

Transport Dwell and Cut-to-Cool Times

Post-harvest technology solutions provide the ability to know – at the pallet-level – how long produce waits in the field and between various way points to the loading dock. You can ensure that cut-to-cool targets are being achieved and maintained.

Precooling Efficiency

In-pallet IoT sensors autonomously monitor for precool timing and effectiveness. Data identifies pallets receiving improper or insufficient cooling to maximize the efficiency of this expensive and often limited resource.

Benefits to Growers

Zest Fresh post-harvest technology provides insights to growers that can positively impact:

Produce quality and freshness

Post-harvest time and temperature are the two most critical variables that affect produce freshness and quality. Time spent at field heat and extended cut-to-cool times can reduce freshness (shelf-life) by days, risking premature spoilage and potentially increasing rejection rates. Zest Fresh utilizes pallet-level data and predictive analytics to dynamically calculate the remaining shelf-life of each pallet to ensure it meets the customer’s freshness requirement.

Operational Efficiency

Zest Fresh provides the data and insights to determine post-harvest bottlenecks or issues in production or processes that can negatively impact operations. These include field to receiving gate, gate to pre-cool, precooling entrance and exit, warehouse entrance and shipping. Once identified, these issues can be corrected to improve operational efficiencies, optimize labor utilization and reduce costs. Reports and alerts are automatically generated enabling workers to make the right decision every time.

Post-harvest Technology for Grocers

For grocers, post-harvest technology provides true transparency across the fresh food supply chain. Grocers can know that produce and proteins have been properly handled from production to delivery as well as gain confirmation about the provenance and authenticity of fresh foods.

Benefits to Grocers

Ensure delivered freshness

Know the dynamic remaining shelf-life of each pallet received at the distribution center and automatically confirm that it meets your freshness requirements. This prevents waste due to premature spoilage, at the store or with the customer, by 50 percent or more.

Improve customer satisfaction

You can differentiate on freshness by knowing with certainty that all of your produce and proteins meets or exceeds your freshness requirements. Gain confidence that produce always looks good on the shelf and delivers complete customer satisfaction and builds loyalty to your store.

Complete visibility and traceability

Document provenance, authenticity and cold chain compliance to improve food safety and supply chain visibilility. Zest Fresh, with optional built-in support for blockchain, provides a comprehensive traceability solution.