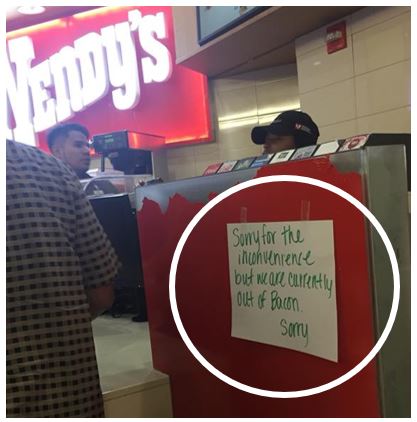

A fast food restaurant running out of bacon? Sounds like my worst nightmare! I remember waking up in a cold sweat one night and immediately racing to my closest 24-hour fast food place. Phew, the bacon cheeseburger was still there. I ordered two, just to be safe.

OK, my nightmare didn’t happen but this one pictured above apparently did and, no doubt, led to a lot of frustrated and unhappy customers at Wendy’s that day. What happened? What went wrong? While it’s hard to say, it could have been:

- The restaurant was incredibly busy that day.

- Something went wrong with the ordering or delivery.

- There was a quality issue with the bacon.

For restaurants and grocers, being out-of-stock or receiving a partial delivery can be a huge problem leading to empty shelves or the inability to fulfill orders. It frustrates customers and can cost you business, not to mention damage your brand’s reputation. You’ve likely seen the recent coverage about Whole Foods stocking issues. While it seems their problem may have been related to a new inventory management system, customers don’t care. They’re just upset that they can’t find the items they need and may take their business elsewhere. The Wendy’s customer may go to McDonald’s and find out they like their bacon cheeseburgers better. The Whole Foods customer may go to Kroger or Safeway and find their produce of equal quality and a better value, never returning to their once beloved Whole Foods.

How can you avoid this nightmare? Well, of course you want to make sure you order properly but what if the strawberries you receive aren’t fresh enough to sell and spoil on the shelf, forcing you to toss them and leaving your produce department out of berries? What if there’s a quality or food safety issue that means you only get half of your order? Or, what happens if the order that was supposed to leave the warehouse or distribution center on Tuesday didn’t leave until Wednesday – and no one told you?

Fact of the matter is, these types of things happen and are often out of your control. The solution is to know what is going on and have the ability to proactively manage your fresh food supply chain.

Zest Fresh delivers this capability. For perishable produce and proteins, Zest Fresh dynamically determines the remaining freshness or shelf-life to ensure the product you receive at the store or restaurant has sufficient freshness for sale and consumption by the consumer. Zest Fresh can also let you know when product has been shipped (and send alerts if there’s an issue) so you’ll know that your order left the warehouse or DC on time – and you’ll also know if it was a full or partial shipment. You can find out more about how Zest Fresh can improve delivered freshness and profitability here.

And, together, we can help ensure that we never run out of bacon (or strawberries or lettuce) again and we can all get a good night’s sleep. Well, unless you live in the UK where you can’t get chicken at KFC!