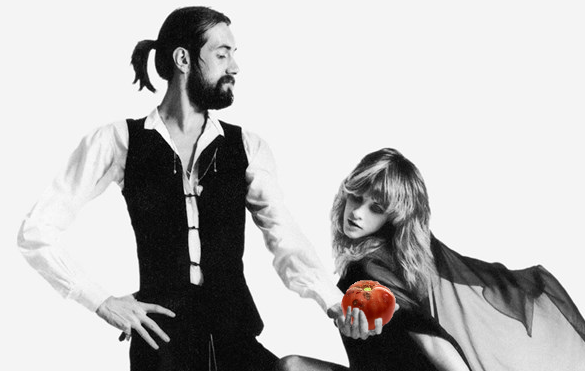

If you’re in my age group, this week’s blog title may take you back to the Fleetwood Mac song from their iconic Rumours album and you may wonder what it has to do with poor quality produce. Well, I’m not going back to 1977 and I’m also not going back to a particular grocery store. Why? Because the produce I purchased there was horrible.

Poor Quality Produce: My Shopping Experience

I had just returned from the United Fresh conference in Chicago and needed to make a quick stop for produce to get me through the rest of the week. On my list: a green bell pepper, a head of lettuce and a clam shell of strawberries. I stopped at a major national retailer on my way home and made a dash to the produce department.

- The green bell peppers were shriveling and showing definite signs of age.

- The iceberg lettuce, which should have several weeks of shelf-life looked “so-so”.

- The strawberries (all of them) were showing (as we call it at the office) “signs of stress,” which is to say they were already changing to a darker red – a sign that they were running out of shelf-life.

I bought them anyway as it was late and I was tired. What happened?

- When I went to use the lettuce, I had to throw two-thirds of the head into the trash because it was spoiling.

- As I used the strawberries, I had to toss some of them immediately as they were spoiling. Some of the berries managed to make it three days. They should have lasted five days or more.

- I didn’t even buy the green bell pepper.

The results: I won’t go back to that grocery store, at least not for produce, and food went to waste.

Why Did the Produce Go to Waste?

Why did this happen? It happened because the retailer didn’t know the dynamic remaining shelf-life of the produce they received, perhaps because they’re using decades-old approaches to managing their fresh food supply chain. Old-style data loggers, for example, can track cold chain integrity (that is, if there was a temperature excursion) but they can’t predict remaining shelf-life.

Worse yet, the grocer may assume that waste that was occurring was due to handling at the store. In fact, the cause of the waste occurs long before the produce reaches the store – it starts in the field.

At United Fresh, there were several exhibitors talking about extending shelf-life through films or packaging and, while there’s nothing wrong with employing these approaches, they still don’t tell you the dynamic remaining shelf-life of the product.

Zest Fresh does.

Avoid Poor Quality Produce: Know its Freshness!

Zest Fresh profiles products to determine their freshness capacity and then, by inserting IoT condition sensors into each pallet of produce at the time of harvest, we apply machine learning and predictive analytics to calculate the dynamic remaining shelf-life.

For example, using Zest Fresh that supermarket chain would have known the strawberries had insufficient shelf-life for sell through and for me to consume them at home before they spoiled. Ditto for the bell peppers and iceberg lettuce.

Instead they’ve lost a customer because of poor quality produce. And I’m not unique in that regard. The quality of produce is one of the major reasons people shop at a specific store or chain. They go for the produce or meats and buy other stuff while they’re there, to the tune of $100-$150 per week. That’s more than $5000 of my business that won’t be going to that store (or perhaps the chain).

Nope, never going back again.