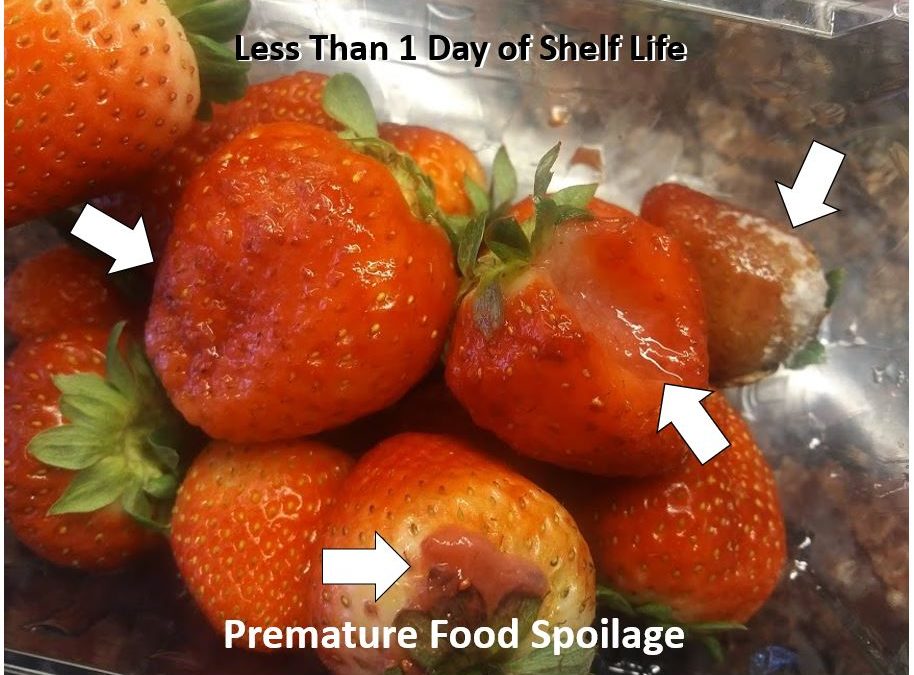

Here’s a food spoilage true story. Over the recent holiday break, I went to my local grocery store (who shall remain nameless) on a Wednesday and purchased a clam shell of name brand strawberries. As usual, they looked fine when I bought them. The next morning, less than 24 hours later, I took them out of my refrigerator and they looked like what you see in the photo above. Mushy. Fuzzy. Inedible.

That morning, I took them back to the store and they offered to exchange them. I went to the produce department and looked for another clam shell and noticed that several of them on display were rotting! On display! How do you think that makes their customers feel, especially at $5 a clam shell?

Aside from going to waste, imagine what this food spoilage experience does to the brand reputation of the grower and the retailer? I’m fortunate in that, within a two mile radius of that store, I have at least seven other major grocery retailers to choose from. If, as the Food Marketing Institute states in their 2018 US Grocery Shopper Trends, the most important attribute when selecting a primary store is quality fruits and vegetables (with a score of 80%), how does this food spoilage experience impact where I or someone with a similar experience would shop?

After I saw the other clam shells spoiling on the shelf, I pointed this out to the produce manager. He went into the back room and brought out berries from a different shipment and commented “It must be the rain.” I presume he checked what he had on display and removed the claim shells with the spoiled berries and tossed them.

This leads to waste and to lost profits.

Is Food Spoilage Driving Your Customers Away – The Financial Impact

But, perhaps more importantly when it comes to food spoilage, from the retailer’s perspective, if his customers are buying those berries and taking them home only to have them spoil, how will those customers react? Will they try another store? If they do, will that become their preferred store? Will that clam shell of spoiled strawberries mean that produce manager has lost a customer who provided perhaps $100-$200 of revenue each week? (That’s what I spend and that reflects the industry average as well.) That’s about $5,000 to $10,000 a year I contribute to that store.

If five customers have a bad experience and take their business elsewhere, that’s maybe $50,000 a year walking out the door.

And what about from the grower’s perspective? I buy strawberries every week and I can tell you that, from my experience, one of the name brands is consistently fresher and of higher quality than another of the name brands. Would a customer stop shopping at a store that consistently stocks an inferior brand and look for a store with the better brand? I can tell you I found that better brand of strawberries at another store less than a mile away, actually closer to my home.

In these days of increasing competition with most shoppers having multiple options – both brick-and-mortar and online – shouldn’t retailers be taking more care to retain customers?

Whose Fault is Food Spoilage?

To be clear, I’m sure my store makes efforts to provide me the highest quality and freshest produce – that’s why I shop there. The problem is that the produce manager can’t determine the remaining freshness of fresh fruits and vegetables by looking at them or checking the “harvest date” label. Visual inspection is a lagging indicator of food spoilage. By the time you see spoilage, it’s too late. So, each morning, they cull through the bins, tossing food that is starting to look bad or spoil prematurely into the dumpster, along with lost profits. And, if an entire shipment is bad – which is what it looks like happened on the day I was there – they may end up out-of-stock on strawberries, an item with high customer demand.

How to Prevent Premature Food Spoilage

The best way to prevent premature spoilage is to understand the cause. Our data shows that the primary causes of premature food spoilage occurs at the pallet level in the first 24-48 hours after harvest due to harvest conditions and post-harvest processing.

For example, if a pallet of strawberries waited five hours for precooling, it could lose five days of shelf-life. That makes a huge difference if the berries were harvested in central Mexico and shipped to California by truck, a journey that could take five days. (If that pallet was shipped from Mexico to New York – they’d spoil on the truck!)

By collecting data about the produce from the time it’s harvested, we can identify any issues that impact freshness and dynamically calculate a freshness metric so that the quality manager at the distribution center and the produce manager at the store can know how much shelf-life remains for each individual pallet. This would have three benefits:

- Prevent wasting food due to premature spoilage,

- Save the retailer money and,

- Perhaps most importantly, keep their customers coming back because they offer consistently fresh produce.

That’s what Zest Fresh does. It helps growers reduce fresh food waste and ensure they’re delivering the consistently freshest produce and helps retailers ensure that their customers keep coming back for more – instead of driving down the street.