Cold supply chain variability is, oddly, a constant. And, the impact of delays and other variables on freshness and quality can be significant.

Politics aside, this issue has been highlighted of late due to delays of getting trucks across the border from Mexico into the USA. According to an article in Fresh Fruit Portal “Producers of strawberries, blueberries, raspberries and blackberries have on average experienced a 20% drop in sales as the extended wait times crossing into the U.S. have resulted in reduced shelf life for the fruit once it arrives in the destination.” (Emphasis added) Another article in Fresh Plaza on April 26 mentions how this problem could drive up prices for produce in the USA.

Long Distance and the Impacts on Cold Supply Chain Variability

Due to year-around demand for fresh produce, significant amounts of fruits and vegetables are shipped long distances from Mexico and Latin America to the United States as well as Canada. Those trips by truck can take five to seven days or more. Even losing a day of shelf-life can be catastrophic for highly perishable products like raspberries, strawberries and leafy greens in the cold supply chain.

This is bad for produce coming from south of the border into California but imagine if it’s being shipped to Vancouver, Toronto, New York or Boston. How much shelf-life does it have left when you receive it?

Pallet-level Variations

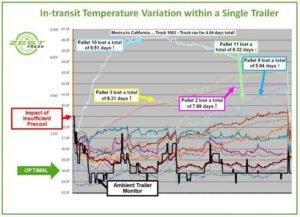

As a truck waits in line at the border (or during any point in transit), how do you know that the produce is being properly refrigerated? Is a trailer temperature logger sufficient? We don’t think so as we have done research that documents that each pallet of produce has a dynamic remaining shelf-life and that there can be significant variation in temperatures and shelf-life between pallets even in a single trailer.

The diagram below charts the temperature of 26 pallets of blackberries making the trip from Mexico to Los Angeles, a five day journey. The dark black line reflects the trailer temperature. The colored lines represent each of the pallets. Notice the variation. Five of the 26 pallets (almost 20 percent) had significant temperature issues on the truck. One pallet aged ten days over the five day journey. Chances are, these pallets would spoil at the store or with the consumer. You can’t likely spot this variation through visual inspections. You need data about each pallet’s actual shelf-life.

Almost Gone Bad

The Fresh Fruit Portal article continues ““They have also been returning two in every 10 trucks, on average, which is to that say that 20% has been affected because when the cargo arrives it has almost gone bad.”

Almost gone bad?

How do you know when produce has almost gone bad? Visual inspection will tell you when produce is going bad but not when it is “about to.” Once you notice shriveling, juicing or mold, it’s already gone bad.

Do you want to sell produce to your customer that is about to go bad?

To ensure quality and freshness across the cold supply chain, you need data about each pallet and how it has been handled beginning at harvest to be able to determine its actual remaining shelf-life. Zest Fresh helps growers, packers and shippers understand the impact of time and temperature on produce from the time of harvest to manage cold supply chain variability all the way to the retailer or restaurant.

With Zest Fresh, you don’t have to guess about the remaining freshness of the produce arriving at your distribution center. You can know that pallet A has eight days of freshness and pallet B has two. You can better identify which pallets to accept and where to route them so that they’re all delivered with sufficient freshness to meet your needs.

Food Safety and Cold Supply Chain Variability

In addition to the impact of temperature on freshness, times spent at warmer temperatures can also increase the risk of pathogen growth and create food safety issues. To help to ensure food has been held at appropriate temperatures from harvest to delivery, you should know the temperature history of each pallet because, as we’ve shown, each pallet can have a significantly different temperature history. If you find a pallet has experienced a temperature excursion, you can automatically flag it for additional inspection.

Managing Your Cold Supply Chain Variability

Zest Fresh helps you manage variability in the cold supply chain. Whether pallets wait in the field prior to precooling or spend more time on trucks due to delays at the border, at every step along the way, Zest Fresh is dynamically updating the remaining shelf-life of your fresh produce providing you the insights you need to improve your operations and delivered freshness.

(Please email me if you’d like a copy of the diagram.)